In the rapidly evolving world of eco-friendly packaging, sustainable materials are no longer optional. Also, around 40% of the world’s plastic waste comes from packaging. Kraft paper boxes are the answer to the difficult problem of consumer’s preference for eco-friendliness. With the ideal balance of environmental friendliness, style, and adaptability, they are revolutionary. Many brands like L’Oréal, McDonald’s, and Zappos promote Kraft packaging and achieve exceptional popularity in the market.

Whether you are a packaging brand owner, a wholesaler, or simply a purchaser, Kraft paper boxes are worth exploring. From rustic brown nature to highly customizable prints, Kraft paper boxes have become innovative choices among brands and individuals alike. BizzCrave provides comprehensive information, including benefits, types, and future trends, about Kraft paper boxes.

What Are Kraft Paper Boxes?

Kraft paper boxes are made from Kraft paper. Wood pulp is extracted using a special method to create kraft paper. Normally, it comes in brown, but can be bleached through various customizable techniques. Kraft paper, being durable and sturdy, holds a wide range of products easily. Many brands and commercial operations use Kraft paper for wrapping and packaging purposes. The earthy and brown hues of kraft paper make it easy to create intricate and refined finishes and paintings. Moreover, their porous nature makes them breathable and ideal for sensitive products.

In 2025, the global Kraft packaging market is projected to be worth USD 43,214.6 million.

Why Kraft Paper Packaging Is Beneficial for Your Brand and the Environment

Kraft paper has established a reputation among brands, whether it is used as a box, bag, or other container. Their beneficial effects are the reason for their popularity. BizzCrave covers a few positive aspects of using Kraft paper for packaging.

Incredible Strength

With the presence of long fibers and high cellulose and low lignin content, Kraft packaging ensures superior protection of the product. They also keep products safe while handling and shipping.

Versatile and Durable

The multifunctional property of Kraft paper makes it flexible and versatile to a wide range of customizations (printed with various inks). Additionally, kraft paper corrugated boxes are the best proof of durability throughout transportation.

Maintain aesthetics

In the world of aesthetics, Kraft packaging gives a rustic charm and creates an organic look that is visually appealing and attractive.

Boundless Customization

To satisfy a variety of consumer preferences, custom kraft boxes provide cutting-edge designs, premium printings, and finishings with extra decorative elements.

User-Friendly

They facilitate customers with easy handling options and clear labeling. Additionally, brands use tapes to prevent opening by chance.

Brand Enhancement

With storytelling features, Kraft Paper boxes increase customer satisfaction and create an emotional connection with the customer and brand.

Reduce Carbon Footprint

Being biodegradable and renewable, they reduce environmental impact and carbon emissions in the external atmosphere.

Sustainable vs Standard: The Difference Between Kraft Paper vs Regular Paper

Kraft paper is different from ordinary paper in a lot of ways. Compared to regular paper, they provide more long-term advantages. The main differences between them are tabulated here.

| Properties | Kraft Paper | Regular Paper |

| Strength | High strength and tear-resistant | Moderate strength, prone to tearing |

| Texture | Rustic/Earthy | Smooth |

| Production Process | Special chemical process | Mechanical or chemical process |

| Cost | Pricey but worth it | Cost-effective, but do not offer the same benefits |

| Carbon Footprint | High | Low |

| Weight | Typically heavier | Lightweight to heavyweight |

| Applications | Packaging, shipping | Printing, writing |

Exploring the Variety: Different Types of Kraft Paper Packaging

Different and high-end varieties of kraft paper were used by brands in industries. The needs of the product dictate the different types of them. Industries, including packaging for fashion and finance sectors, bleach some of the Kraft paper to achieve the desired colors, even though it is naturally strong and brown. Here, we list the different kinds of Kraft paper packaging according to their style and material.

Material-Based Kraft Paper

Virgin Kraft Paper

With 5% of recycled material, this type of kraft paper is employed in heavy-duty applications. The nature of this paper offers suitable marking and logos for printing. This paper is not quite heavy but can hold heavy items. This paper is also used in the manufacturing of corrugated boxes.

Recycled Kraft Paper

Kraft paper has been recycled, as the name suggests. A paper will lose some of its strength after recycling. So, recycled Kraft paper has low tear resistance and breaks down more easily than virgin Kraft paper. It is extensively utilized in box liners, paint masking, newspaper bottom wrapping, and textile wrapping.

Mixed Kraft Paper

A blend of different fibers, and the production process results in mixed kraft paper. Different types of woods, fibers, and additives are used in making such paper. Its top-notch benefit is cost-effectiveness because of recycled properties and used in multiple packaging purposes.

Style-Based Kraft Paper

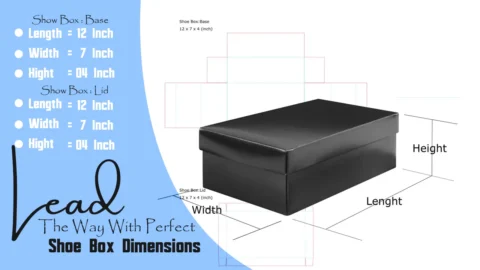

Kraft Boxes with Lids

There is a lid on top of these boxes. They keep the product from falling out. These lids support the contents within and demonstrate their temperature when used with box inserts. These boxes can hold items like gifts, shoes, cosmetics, and various clothing.

Kraft Window Boxes

The best way to display multiple products like edibles, cosmetics, or retail items. These boxes possess some window cutouts and a fine transparent film is used in that cutted section to secure the products. These boxes build customers’ trust towards respective brands due to their confident display of features.

Kraft Pillow Boxes

An elegant and fancy style of these boxes, concerning a pillow, makes them highly appealing. They can be open from dual sides and opt for little storage space. Items like chocolates, confectioneries, hair accessories, or delicate jewellery can easily be packed in them.

Kraft Gable Boxes

These are composed of unbleached wood pulp and are a durable and robust addition. They are user-friendly due to the small handles on the top side. They have an easy-to-assemble option if they are shipped flat. These boxes can be used as wedding favors or to store salads and hot food items.

The Hue Factor: Understanding the Color Classification of Kraft Paper Boxes

The topic of turning Kraft paper’s original brown hue into various other hues will now be covered. You can easily bleach the Kraft paper to create different color formats.

Brown Kraft Paper

Chemicals such as sodium hypochlorite or hydrogen peroxide can be used to lighten the natural kraft paper’s dark brown hue. Their subsequent oxidation reduces the brown color’s dark intensity to light brown. Due to the bleaching process, the light brown kraft paper slightly loses its strength. You can wrap, package, craft, and more with this Kraft paper.

White Kraft Paper

These kinds of Kraft paper are produced by bleaching natural Kraft paper with high chemical concentrations. Multiple bleaching agents are used to achieve the desired level of whiteness in order to completely remove lignin and chromophores. Excessive bleaching weakens the paper and decreases its ability to withstand tears. These Kraft papers are commonly used to package lightweight fashion items and accessories.

Black Kraft Paper

To get the dark back color, regular kraft paper is coated instead of bleached. The paper can be made black by using black inks or toners. The additional coating process gives the black kraft papers greater durability and strength. It is utilized in banners, wrappings, and bulletin banners.

Colored Kraft Paper

Kraft paper can be transformed into various colored kraft papers by combining complex dyes or pigments with a variety of printing techniques (such as screen or digital printing). They can be made into kraft paper with pastel, bright, or earth tones. These printing customizations stand out in the market and attract more customers.

Print Perfection: Unveiling Top Techniques for Kraft Paper Packaging

- Offset Printing: It is of high quality with color accuracy and proper surface perfection. This technique is versatile and cost-effective for large runs with detailed graphics.

- Flexographic Printing: An extremely fast method that incorporates adjacent processes like varnishing, embossing, and slitting and can handle a variety of ink forms.

- Litho-laminated Printing: The best print quality technique that guarantees the hues in the design look vibrant and accurate. It is a powerful combination of visual excellence and structural resilience.

- UV Coating/Spot UV: A popular technique that is a coating and not printing itself, applied on specific areas. It creates a smooth texture that enhances the tactile experience.

- Foil Stamping: Application of thin metallic foil on the surface with the help of heat and pressure. It gives premium and luxury appeal to the customers.

The Final Touch: Mastering Finishing Techniques for Kraft Paper Boxes

- Gloss or Matte Lamination: A high luster and shiny look is the result of a polished look. On the other hand, a matte finish is non-glossy, glare-free, proficient, and elegant.

- Embossing/Debossing: Embossing enhances the striking appeal by producing an upward 3D appearance. Particularly on thick stock, debossing produces a recessed, lowered design that has less effect on the other side.

- Varnishing: An additional layer of protection against hand prints and scrapes is offered by a clear, transparent coating.

- Aqueous Coating: It is a water-based coating that offers medium to high splenliness and is less likely to yellow over time.

Pulping to Packaging: The Kraft Paper Production Process

Making kraft paper requires a precise, step-by-step procedure. These procedures are followed by several succeeding brands to create professional-grade Kraft paper boxes.

Step 01: Wood Pulping

Wood pulping, the initial stage of making kraft paper, entails cooking a lot of wood chips with chemicals (NaOH and NaSO3). Manufacturers used chemicals in addition to mechanical forces to separate the fibers. Kraft paper’s strength is determined by the purity of the pulping process.

Step 02: Screening

Screening is done to enhance the extracted pulp. Dirt and other impurities are removed. For improved paper formation, this step guarantees pulp uniformity and even distribution. To produce high-quality kraft paper, screening also lessens flaws like rips, holes, and weak spots.

Step 03: Forming Paper

Water begins to drain from the prepared and screened pulp after it is poured into a wire mesh screen. Fibers are left over after this draining, and they are subsequently joined to create a mat. To make the paper flat and remove excess water, a machine rolls it down.

Step 04: Drying

Then, using a hot air or steam-heated cylinder, the paper is dried by passing it through various drying sections at a regulated temperature.

Step 05: Making Kraft Paper Boxes

After the Kraft paper has been manufactured, different brands and industries use it in making boxes, bags, or any kind of container. They cut the kraft paper into their desired designs, make memorable prints on them with multiple printing techniques.

Step 06: Finishing and Packaging

Experts use practical finishing techniques to enhance the boxes’ aesthetic appeal once they are decorated. After stacking them into shipping boxes, they dispatch them for delivery.

From Warehouse to Store: Industrial Uses of Kraft Paper Packaging

Kraft paper packaging is used in many industries because it is robust and durable. Despite other packaging, Kraft paper packaging contributes to cost-effectiveness for the well-being of budgets of customers. Here are some top industries that prefer to use Kraft paper packaging to package their valuable products.

- Food and Beverage Industry

- Gift Packaging Industry

- Cosmetic Industry

- Pharmaceutical Industry

- Automotive Industry

- Furniture and Homeware

- Electronics

Final Words!

To conclude, Kraft paper packaging is a robust and adaptable addition to the packaging sector. Kraft paper boxes come in a variety of colors, from bleached to natural brown, and serve a variety of purposes. When compared to ordinary paper, it is a desirable alternative for a variety of commercial enterprises looking to improve their reputation on an industrial scale. You should share this guide with your colleagues if you find it useful. Thanks!

FAQs

Is There Any Demand for Kraft Paper Packaging in the Future?

Yes, in the future, the applications of kraft paper are expanding and expected to improve quality and functionality.

Can I Review a Brand That Achieves Success By Using Kraft Paper Boxes?

Hardy, CaliWoods, and Zoomin are successful brands that achieve their goal by using Kraft paper packaging.

Are Kraft Boxes Moisture Resistant?

Yes, Kraft boxes provide resistance to moisture or humidity.